Amino Acid Organic Acid

Zymotic fluid (e.g. nucleotide, antibiotics, organic acid etc. ) mycelium separation usually adopts plate-frame filtration and centrifugation separation, that makes not only work strength high but separation precision is low, product recovery rate is not high. Also, the succeding operation washing water consumption is large, COD discharge value more high, cause the environmental pollution.

Ceramic membrane had become to the separation technique prior selected for biological fermentation industry because of its special performances such as chemistry corrosion resistance, high temperature resistance, high separation precision etc. Ceramic membrane can largely be used in the fermentation liquid treatments such as fermentation organic acid (e.g. citric acid, lactic acid, itaconic acid etc.), antibiotics (e.g. penicillin, erythrocin etc. ), vitamin (e.g. vitamin B2, vitamin B12 etc.), amino acid etc. It removes the mycelium, big molecule protein, Yeast bacterial wall fragment and cell fiber etc., which reduce the treatment cost and treatment load of lower reaches process like resin exchange, active carbon adsorption etc, improve product recovery rate, waste water load be reduced greatly. Same time, the protein recovered from fermentation liquid can be the animal feed.

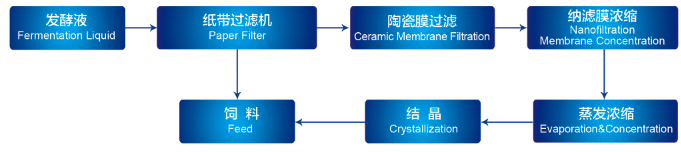

Process Flow

Technology Characteristics

High separation precision, clear transparent permeate liquid, greatly reduce the load of lower reaches refining process;

Chemical additives are not needed, concentration material (mycelium, proteins etc. ) can be recovered as seed;

Assure the wholeness and activity for fermenting cell of above 95%;

Super contamination resistibility, good regeneration performance, long work life;

Achieve high expansion concentration of fermentation liquid, improve products recovery rate;

Achieve cleaning production, save the washing water volume for acid and alkali, also enhance the biodegradability of wastewater.

PLC control, handle simple and easy, depress labor intensity.

Application Products

Amino Acid class: diaminocaproic acid, glutamic acid, alpha-amino-beta-hydroxybutyric acid, tryptophan, glycin etc.

Organic Acid class: lactic acid, citric acid, succinic acid, adipic acid etc.

Vitamin class: vitamin c, vitamin B2 etc.